Industrial Process Controls: HMI vs Panel PC

Managing the manufacturing processes of a modern industrial facility is no small task. Facilities must maintain a reliable network of systems to control, track, and report on all aspects of facility operations. The physical touchpoints where operations personnel interact with these industrial systems are the human-machine interfaces (HMIs).

Managing the manufacturing processes of a modern industrial facility is no small task. Facilities must maintain a reliable network of systems to control, track, and report on all aspects of facility operations. The physical touchpoints where operations personnel interact with these industrial systems are the human-machine interfaces (HMIs).

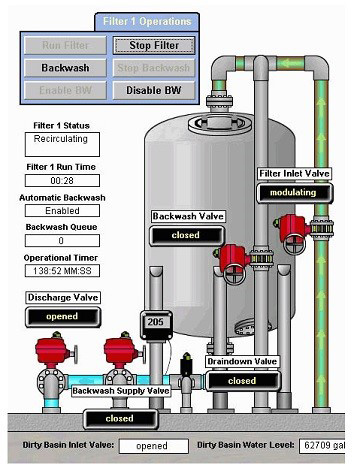

The most common examples of industrial HMIs are control panels and/or touchscreens that display information about a process or machine and allow an operator to interact with the HMI to affect a change on the process or machine it is connected to. Such changes can be carried out manually at the HMI panel device or remotely.

HMI functions can be handled remotely by utilizing a supervisory control and data acquisition (SCADA) system. SCADA control systems are generally used to control large-scale industrial processes in industries such as water, oil, gas, data, and electric. “Based on data received from remote stations, automated or operator-driven supervisory commands can be pushed to remote station control devices, which are often referred to as field devices. Field devices control local operations such as opening and closing valves and breakers, collecting data from sensor systems, and monitoring the local environment for alarm conditions.” – National Institute of Standards and Technology

Common Uses of HMIs

HMI units are essential to managing industrial processes efficiently and with expedience. Once an operator initiates an action from an HMI device, a connected programmable logic controller (PLC) module executes a simple command to open a valve, sound an alarm, stop a conveyor belt, send an alert message, etc. Some common tasks performed by industrial systems that use HMIs and PLCs are:

- Sounding alarms

- Generating messages

- Capturing sensor input

- Transmitting data

- Displaying system status

- Controlling machines

- Stopping/starting processes

HMI Shortcomings

Many industries have widely adopted HMIs as the standard machine and process control devices within their operations. They house no moving parts (fans) and are highly specialized, leading to a low-cost control solution. Nonetheless, they lack flexibility. For example, if your HMI device fails at a given access point, you will need to have a spare unit handy; and the spare unit needs to have the exact same configuration as the failed unit, or you will damage productivity while securing or reconfiguring another unit. You can mitigate this risk by keeping spare units handy with matching configurations, but this type of emergency plan can be an expensive proposition.

Many industries have widely adopted HMIs as the standard machine and process control devices within their operations. They house no moving parts (fans) and are highly specialized, leading to a low-cost control solution. Nonetheless, they lack flexibility. For example, if your HMI device fails at a given access point, you will need to have a spare unit handy; and the spare unit needs to have the exact same configuration as the failed unit, or you will damage productivity while securing or reconfiguring another unit. You can mitigate this risk by keeping spare units handy with matching configurations, but this type of emergency plan can be an expensive proposition.

In today’s information and data-driven world, process engineers and facility managers need actionable insights and feedback to continuously improve their processes. HMI devices require the assistance of SCADA software to track, record, and report process information in a way that is both helpful and actionable for process engineers. Designing, building, and maintaining a vast and intricate network of devices as part of a facility SCADA system can be a monumental undertaking.

HMI Alternative: Panel Mount Computers

While there are still a few select industrial applications where HMIs may still be the preferred process control devices, they are rapidly losing industry support. Panel mounted PC solutions are taking over as the most common process control devices due to their exceptional functionality and data processing abilities.

While there are still a few select industrial applications where HMIs may still be the preferred process control devices, they are rapidly losing industry support. Panel mounted PC solutions are taking over as the most common process control devices due to their exceptional functionality and data processing abilities.

If an industrial panel PC fails, it can be more easily configured compared to a highly specialized HMI device. This cuts down on the cost of required on-hand emergency inventory and helps to maximize operational uptime.

HMI and PLC process control devices also do not have sufficient on-board storage for critical reporting data. This forces the devices to transmit operational data to remote servers. Should network connectivity suffer a failure, this critical information will be lost when the device fails to successfully transmit its data. However, with an industrial panel PC, there is ample storage space for critical reporting data. In the event of a network failure the information can simply be stored locally until connectivity has been restored.

When compared to the limited functional abilities of HMI and PLC devices, an industrial panel PC is vastly superior. The computing abilities afforded to this type of device enable facility managers to utilize robust process management software packages in their operations; greatly improving the amount and quality of the data being captured by the process. Additionally, since PC based systems can handle multiple functions simultaneously, fewer access points are needed in the facility compared to an HMI/PLC solution.

Industrial Panel PC Solutions

Teguar Corporation offers a wide selection of high-quality, customizable panel computer solutions. Outfitted with industrial-grade computer components, Teguar products are “Made to work where you work, when you work and how you work,” and designed to your specifications. Built to withstand the abuse of harsh environments, Teguar offers a wide range of industrial-grade computer solutions with waterproof and fanless options.