What Makes an Industrial Touchscreen Industrial?

Too often in life, it’s easy to get lulled into a false sense of security by marketing. You may purchase “heavy-duty” trash bags one day, only to find yourself cleaning up an industrial-sized mess the next day when the bottom falls out of your “heavy-duty” bag and trash tumbles onto your floor.

So if you’re in the market for an industrial touchscreen, nobody would blame you for wondering: What makes an industrial touchscreen industrial? In this article, we will talk about what it means for a touchscreen to truly be industrial—and why it may be important for your application.

Three Elements of Industrial Touchscreens

An industrial touchscreen is designed and tested for harsher environments, making it much more rugged compared to typical commercial monitors. These computers need to be able to handle constant use. While the touchscreen is usually the most delicate part of a unit, industrial computers need to be rugged all over. With that being said, what specifically makes an industrial touchscreen industrial? There are three main elements.

Industrial Touchscreen Element 1: GLASS

It seems like nowadays every electronic device in our possession has a chance of being shattered. If you drop your iPhone face down on the ground, you hold your breath while picking it up in anticipation of it being broken. Laptops could be accidentally jostled and then the screen turns funky colors. When working in applications where there is constant risk of dropping and harsh environment factors, the touchscreen needs to be able to handle it all.

The Mohs Hardness Scale is used to identify and determine the hardness of a mineral. The scale ranges from 1 to 10, with glass around an average “5” and diamond at the top of the scale with a “10”. Combining this scale with the suffix “h” is used for touchscreen hardness. “h” means the hardness of a pencil. Manufacturers go through the “pencil test”, comparing the relative hardness of a screen. When someone declares their screen to be 9h, it means the screen can resist scratches from the hardest pencil.

Gorilla Glass by Corning is a glass used in most industrial touchscreens. This glass is chemically strengthened to be able to withstand the toughest environments, falling at around 7h on the Mohs hardness scale.

While strength of the glass is extremely important, it is also beneficial to know what touchscreen type is needed. Industrial touchscreens often come in either resistive or projected capacitive (PCAP) touchscreens. Resistive touchscreens are reliable and responsive to both bare and gloved hands. PCAP screens are more scratch resistant and have multitouch sensibility.

Industrial Touchscreen Element 2: BRIGHTNESS

Sunlight readable liquid-crystal displays (LCD) are a common feature when shopping for an industrial touchscreen and panel PCs. This refers to the brightness of the screen measured in Nits. Typical LCD panels have a screen brightness between 250 Nits to 450 Nits. LCD brightness of 800 Nits or higher is generally considered sunlight readable, but most sunlight readable displays are 1000 Nits. Increasing the brightness of the LCD panel backlight is the most common method of making an LCD panel sunlight readable.

It’s important to note that an industrial touchscreen’s ability to be classified as sunlight readable does not mean that it’s safe to expose the screen to direct sunlight all day, every day. Typically a cover or hood is required to protect the touchscreen from constant, prolonged exposure to UV rays. Limited exposure is fine, however, and in situations where the screen needs to be read and used in sunlight, visibility will be no problem with one of these sunlight readable screens.

For industrial touchscreens in outdoor environments, a sunlight readable LCD is desirable. It allows users to be able to accurately see their screen in direct sunlight. Sunlight readable LCDs are also often used in indoor applications where bright sunlight through windows occur, such as air traffic control centers, railroad cars, marine vessels, agriculture machinery, and public kiosks.

Industrial Touchscreen Element 3: WATERPROOF RATING

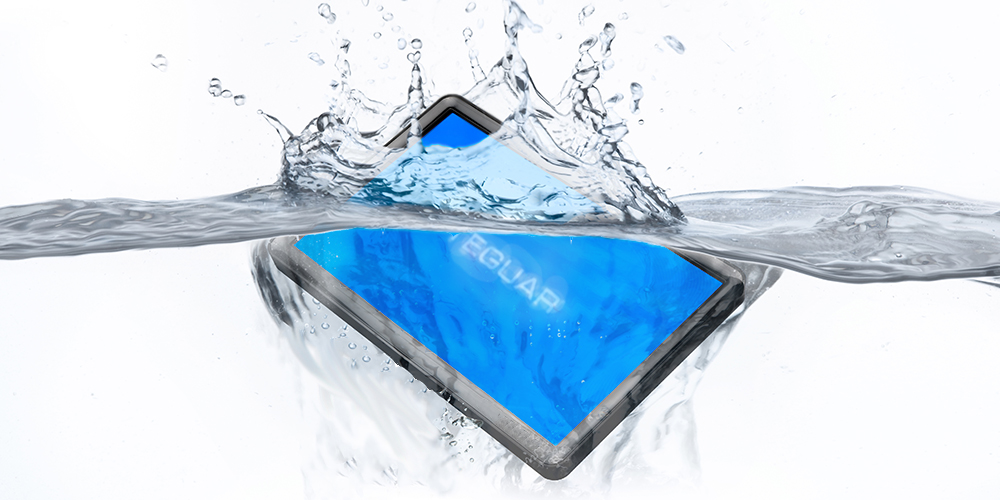

Another important feature of industrial touchscreens are their ability to withstand cleaning and washdowns due to their Ingress Protection (IP) rating. This is a universally accepted way to measure an electronic device or enclosure’s protection against dirt or liquids.

Most industrial touchscreens have an IP rating of IP66 or above- meaning they are totally protected against dust and low-pressure jets. This is ideal for most industrial environments where cleaning is frequently necessary.

If you would like to learn more about IP ratings and what is best for your application, refer to our Knowledge Center article entitled ‘IP Rating on a Computer: What is it Good For?‘

When are Industrial Touchscreens Necessary?

In normal office settings, a sunlight readable Gorilla glass waterproof touchscreen isn’t often needed. However, in many industrial settings, these features are all necessary. If you are looking to upgrade to an industrial touchscreen, please contact one of our knowledgeable Teguar product specialists by calling +1 800 870 7715 or contacting us online.

Resources Used

https://www.nps.gov/articles/mohs-hardness-scale.htm

https://saharacase.com/blogs/saharacase-tech-news/what-is-9h-hardness

About the Authors:

Emily Vrettos, Teguar's Digital Marketing Coordinator, merges her creativity with marketing skills to craft engaging content. When she isn’t writing, she loves to read, cook lots of different cuisines, and travel home to her family in New England.Previous Article

Industrial Monitor & Box PC Vs. Industrial All-in-One - Which is Right for Your Application?