Capacitive vs Resistive Touchscreens

When it comes to choosing a touchscreen for your industrial or medical application, it is crucial that you understand the most popular types of touchscreens, in order to find the best solution. In the video below, Tom Poplawski and Will Hoffarth demonstrate how capacitive and resistive touchscreens work.

Capacitive Touchscreens: Projected and Surface

There are two types of capacitive touchscreens: projected capacitive and surface capacitive. The two work similarly and as a user, it is difficult to differentiate between them. Projected capacitive is the more common type of touchscreen and it is what Teguar uses on many industrial and medical computers and tablets.

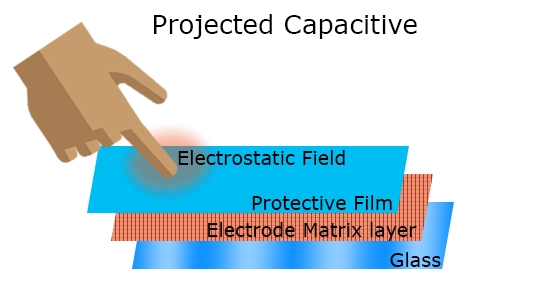

Projected Capacitive Touchscreens

Projected Capacitive (PCap) touchscreens are used on the vast majority of smartphones and tablets. PCap screens consist of a layer of glass, a matrix of electrodes and a protective film. The matrix of electrodes creates a three dimensional electrostatic field that registers even the slightest change in electrical current. So, when a conductive object, such as your finger or a stylus, comes into contact with the matrix of electrodes, the electric field is changed slightly, and the screen registers your touch.

Projected Capacitive (PCap) touchscreens are used on the vast majority of smartphones and tablets. PCap screens consist of a layer of glass, a matrix of electrodes and a protective film. The matrix of electrodes creates a three dimensional electrostatic field that registers even the slightest change in electrical current. So, when a conductive object, such as your finger or a stylus, comes into contact with the matrix of electrodes, the electric field is changed slightly, and the screen registers your touch.

- Best Image Clarity

- Best Scratch Resistance

- Multi-touch Capability

- Registers Touch with Thin Gloves (such as surgical gloves)

Surface Capacitive Touchscreens

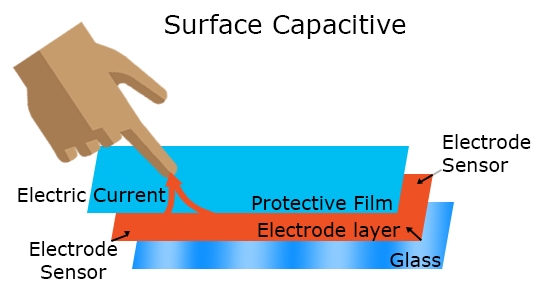

A Surface Capacitive touchscreen consists of a layer of glass, a layer of electrodes, and a protective film. The layer of electrodes has a constant charge and when you touch the screen with your bare finger or a capacitive stylus, a tiny amount of that charge (or electric current) is transferred from the screen to your finger. Sensors at each corner of the touchscreen locate where the electric current is transferred and that is where the screen registers your touch.

A Surface Capacitive touchscreen consists of a layer of glass, a layer of electrodes, and a protective film. The layer of electrodes has a constant charge and when you touch the screen with your bare finger or a capacitive stylus, a tiny amount of that charge (or electric current) is transferred from the screen to your finger. Sensors at each corner of the touchscreen locate where the electric current is transferred and that is where the screen registers your touch.

- Best for Large Size Touchscreens

- Used in Public Kiosks and Interactive Displays

Resistive Touchscreens

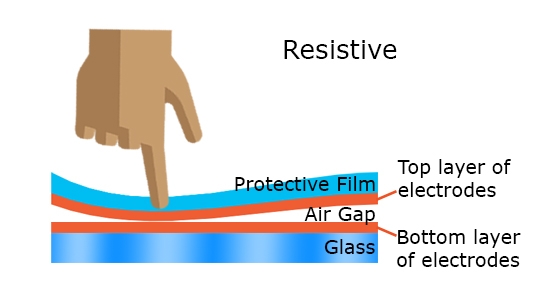

Resistive type touchscreens consist of a panel of glass and protective film screen that are separated by a very small air gap. The sides of the glass and film that face each other are coated with a thin metallic layer of electrodes. When you apply pressure to the film (i.e. you touch the screen), the two electrode layers touch, completing an electrical circuit and registering touch. Spacer dots are used to determine where the touch point is.

Resistive type touchscreens consist of a panel of glass and protective film screen that are separated by a very small air gap. The sides of the glass and film that face each other are coated with a thin metallic layer of electrodes. When you apply pressure to the film (i.e. you touch the screen), the two electrode layers touch, completing an electrical circuit and registering touch. Spacer dots are used to determine where the touch point is.

You can use virtually any object on a resistive touchscreen, which makes it ideal in manufacturing environments where users wear thick gloves.

- Not as Accurate or Smooth as Capacitive

- Pressure Sensitive

- Registers Touch from any Type of Glove or Object

- Lowest Cost Touchscreen Solution

- Best when there are strong electric currents in the air or potential conductive substances (water) on the screen

Most of Teguar’s waterproof computers are available with resistive touchscreens, as wash downs with waterjets or chemicals will interfere with a capacitive touchscreen. Teguar industrial computers vary, some lines are available with resistive touch and some are only available with PCap. If you have questions about touchscreen types or want to discuss your project, contact us.

Previous Article

Teguar’s New Explosion Proof Computer TSX-5010-15 is Built for Hazardous Locations