Why Panel PCs Outperform Desktop PCs in Harsh Industrial Environments?

When making a decision on the computing equipment to use in industrial settings, engineers and IT managers frequently face the critical choice between using Panel PCs or traditional Desktop PCs. It’s a bit like choosing between a specialized off-road vehicle built for rugged terrain and a standard sedan designed for city streets. While desktop computers have long been the staple for general office use, the harsh and demanding environments of industrial applications necessitate specialized solutions. Let’s delve into a technical comparison, highlighting why desktop PCs often fall short in industrial contexts and how panel computers truly shine.

What Exactly is a Panel PC?

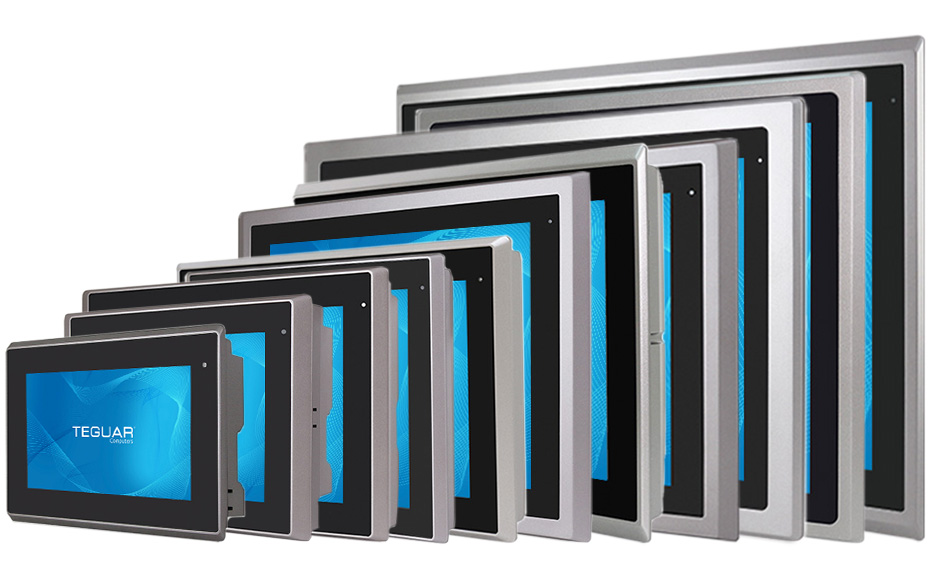

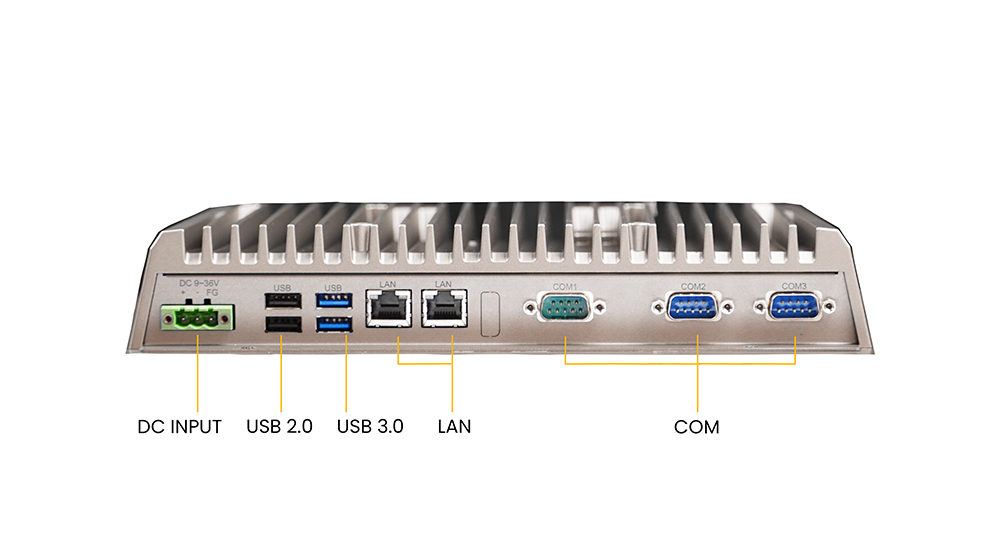

Imagine an all-in-one industrial computer that’s completely integrated into a display unit. That’s a Panel PC. Unlike a traditional desktop setup, where the monitor, CPU, and peripherals are separate components scattered across a workspace, a Panel PC consolidates everything into a single, robust, and often fanless enclosure. This integration includes a high-brightness LCD display, an industrial-grade motherboard and processor, like Intel Celeron and Core i3/i5/i7, ample memory, and hard drive storage. You’ll also find a comprehensive set of input/output (I/O) ports, all neatly tucked away. They’re designed to be mounted directly into control panels, walls, or VESA mounts, offering a streamlined and space-saving solution. Key characteristics often include ruggedized construction, sealed bezels for dust and liquid protection, wide operating temperature ranges, and impressive resistance to shock and vibration.

Why Desktop PCs Don’t Cut It in Industrial Settings

While perfectly at home or in an office, desktop computers often struggle in the rough-and-tumble world of industrial environments. Their design prioritizes cost-effectiveness and general-purpose use, not the kind of durability and resilience needed when things get messy.

Think about a manufacturing plant or a busy warehouse. These places are often a far cry from a sterile office. Here is a list of reasons where desktop computers fall short.

- Industrial spaces are frequently full of dust, metal shavings, chemical residues, and other airborne particles. desktop PCs rely on active cooling systems with fans, which act like tiny vacuums, sucking in all these contaminants. This quickly clogs heatsinks, impedes airflow, and leads to overheating, component degradation, and premature system failure. It’s like trying to run a marathon with your lungs full of cotton balls.

- Splashes, spills, washdowns, and high humidity levels are commonplace in many industrial sectors, especially in places like food processing or pharmaceuticals. Standard desktop enclosures offer little to no protection against liquid ingress. Even a small splash can short-circuit components, leading to catastrophic failure and potential safety hazards.

- Industrial facilities can experience dramatic temperature fluctuations, from freezing cold to scorching hot. Commercial grade desktop components are typically rated for a narrow operating temperature range, usually between 0∘C and 35∘C. Operating outside this comfort zone can lead to performance throttling, instability, and permanent damage to sensitive electronics.

- The constant hum of machinery, material handling equipment, and even the vibrations from transportation can be brutal. desktop PCs, especially those with traditional spinning hard drives (HDDs), are highly susceptible to these forces. Even minor vibrations can cause read/write errors, corrupt data, and lead to the mechanical failure of hard drives. Loose connections on expansion cards and internal cabling are also frequent headaches.

Desktop PCs, with their separate towers, monitors, keyboards, and mice, demand a lot of desk or cabinet space. In tightly packed industrial control rooms or on manufacturing floors, real estate is often a precious commodity. The tangle of cables for power, video, USB, and network connections creates a messy web, posing tripping hazards, making troubleshooting a nightmare, and increasing the risk of accidental disconnections. This spaghetti of wires also complicates cleaning and maintenance.

While consumer desktops offer plenty of USB and display ports, they often lack the specialized industrial I/O necessary for connecting to legacy equipment, programmable logic controllers (PLCs), sensors, and other control systems. Common industrial interfaces like multiple serial ports (RS-232/422/485), digital I/O, and CAN bus are rarely found on standard desktops. This forces users to rely on external converters or expansion cards, adding complexity and creating more potential points of failure.

Where Panel PCs Truly Shine

Panel PCs are engineered from the ground up to solve the very problems that plague desktop PCs in industrial environments. They offer a compelling suite of benefits and advantages.

Built like a tank, industrial panel PCs are like armored vehicles with unmatched environmental protection in the industrial world. Coming in different screen sizes from 7 inch all the way up to 24 inch, they typically feature IP-rated front bezels, ranging from IP65 to IP69K. This means they can be resistant to dust, water jets, and even high-pressure, high-temperature washdowns. The fanless design is a game-changer, eliminating any openings for contaminants to enter the system. With industrial-grade components, like extended temperature RAM and solid state drives, industrial panel PCs can operate reliably in extreme temperatures, often from -20∘C to 60∘C or even wider ranges. They shrug off temperature swings that would make a desktop PC wilt. Panel PCs are designed with robust chassis, often using anti-vibration mounting techniques and incorporating SSDs (solid state drives) as standard. Since SSDs have no moving parts, they are virtually immune to vibration and shock damage, ensuring your data stays safe and your system remains stable. Some boasts stainless steel or aluminum enclosures, offering superior resistance to corrosion in harsh chemical processing plants or even marine environments.

As if you need more reasons why panel PCs are the standard type of computer systems used for industrial purposes, these pcs are sleek, integrated, and space saving. The all-in-one design is a breath of fresh air in crowded industrial spaces. By integrating the display and computer unit, it eliminates the need for separate components, drastically reducing the physical footprint. This is invaluable in compact control panels, kiosks, or on equipment where every inch counts. Installation is significantly streamlined. There’s only one unit to mount and far fewer cables to manage, cutting down on installation time and complexity. With fewer external components, cable clutter is dramatically reduced. This isn’t just about aesthetics; it improves safety by minimizing tripping hazards and makes troubleshooting and maintenance much simpler.

Where panel PCs truly earn their keep is rock solid reliability and less downtime. The absence of moving parts like fans significantly reduces the risk of mechanical failure, improves dust resistance, and eliminates noise. This contributes to a much higher Mean Time Between Failures (MTBF), meaning your system stays up and running longer. These computers use components specifically chosen for their durability, longevity, and consistent performance in demanding conditions. This translates to greater system stability and fewer unexpected failures. The sealed designs allow for direct wiping or even hosing down (depending on their IP rating) without fear of damaging internal components. This simplifies sanitation and maintenance, especially in hygiene-critical industries.

I/O ports flexibility is important for industrial usage. panel PCs come loaded with the right connections for industrial environments. They are purposely built with a comprehensive array of industrial communication interfaces. This often includes multiple isolated RS-232/422/485 serial ports for connecting to legacy devices, numerous Gigabit Ethernet ports for network redundancy or device connectivity, and plenty of USB ports.

Finally, the integrated display of a panel PC is almost always a touch screen, built specifically for industrial use. Whether it’s resistive touch for gloved operation or projected capacitive (PCAP) multi-touch for smartphone like gestures, these screens are designed for enhanced durability, scratch resistance, and often feature optical bonding for improved readability in bright light. This makes human-machine interaction (HMI) intuitive and efficient, right where the action is.

Panel PC manufacturers like Teguar often offer a high degree of customization. You can choose your processor, memory and storage configurations, specific I/O port layouts, and even opt for custom branding. This means you can get a system precisely tailored to your application requirements, without paying for features you don’t need.

The Final Word

The choice between panel PCs and desktop PCs for industrial usage isn’t just a matter of personal preference, it’s a critical engineering decision that significantly impacts system reliability, operational efficiency, and your overall budget. While desktop computers might seem cheaper initially, their inherent vulnerabilities in industrial environments inevitably lead to higher maintenance costs, increased downtime, and ultimately, a negative impact on productivity. It’s like buying a cheap umbrella only to have it turn inside out in the first strong gust of wind.

Conversely, panel PCs are specifically designed to withstand harsh environments. Their ruggedized construction, integrated design, rich industrial I/O, and commitment to long term availability make them the clear superior choice for challenging industrial applications. Investing in panel PCs translates directly into enhanced system stability, reduced operational expenditures, and a more robust and reliable computing infrastructure capable of withstanding the rigors of modern industrial environments. For any demanding industrial application, the long-term benefits and operational advantages of a panel PC far outweigh the superficial appeal of a general-purpose desktop computer.

Previous Article

Excitement Builds as Teguar Incorporates New European Branch in 2025