Teguar Panel Mount PCs vs All-In-One Computers

Industrial Panel PCs

Many customers know exactly what they are looking for in an industrial touchscreen computer, but there is still room for confusion regarding form-factors and mounting styles. I would like to take this time to clarify the different mounting types available for panel PCs. For simplicity, touchscreen computers and industrial monitors can be separated into two categories based on mounting styles, panel mount PCs and non-panel mount PCs.

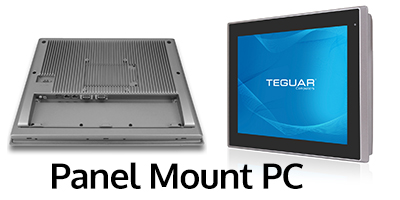

Panel Mount PCs

Panel mount computers are designed to be mounted into a cutout in an enclosure. These enclosures could be a Hoffman box, cabinet door, kiosk, the chassis for a CNC machine, or any other OEM enclosure design. When panel mounted into a cutout in an enclosure, the front face of the panel PC sits flush with surface of the enclosure, and the I/O ports are available to access inside the enclosure. Each panel mount computer includes a front bezel that is slightly larger than the recommended cutout. The panel PC is pushed into the cutout from the front side, and the front bezel overlaps the cutout area. The panel PC is held in place by panel mount clips that are attached around the rear perimeter of the panel PC. The panel mount clips include screws that can be tightened against the enclosure’s interior surface to hold the panel PC in place. The screws do not penetrate the enclosure surface, but they provide force against the enclosure to hold the panel PC snug against the enclosure surface. Teguar’s panel mount panel PCs include an IP66 or IP69K front bezel. When the panel PC is mounted into a cutout in an enclosure, the front side of the enclosure can maintain an IP66 or IP69K protection rating, so they are protected from liquids and cleaning procedures. If frequent wash downs are required, Teguar recommends a stainless-steel bezel to protect from oxidation and corrosion over time. Teguar offers a stainless steel front bezel option on many of our panel mount touchscreen computers.

Panel mount computers are designed to be mounted into a cutout in an enclosure. These enclosures could be a Hoffman box, cabinet door, kiosk, the chassis for a CNC machine, or any other OEM enclosure design. When panel mounted into a cutout in an enclosure, the front face of the panel PC sits flush with surface of the enclosure, and the I/O ports are available to access inside the enclosure. Each panel mount computer includes a front bezel that is slightly larger than the recommended cutout. The panel PC is pushed into the cutout from the front side, and the front bezel overlaps the cutout area. The panel PC is held in place by panel mount clips that are attached around the rear perimeter of the panel PC. The panel mount clips include screws that can be tightened against the enclosure’s interior surface to hold the panel PC in place. The screws do not penetrate the enclosure surface, but they provide force against the enclosure to hold the panel PC snug against the enclosure surface. Teguar’s panel mount panel PCs include an IP66 or IP69K front bezel. When the panel PC is mounted into a cutout in an enclosure, the front side of the enclosure can maintain an IP66 or IP69K protection rating, so they are protected from liquids and cleaning procedures. If frequent wash downs are required, Teguar recommends a stainless-steel bezel to protect from oxidation and corrosion over time. Teguar offers a stainless steel front bezel option on many of our panel mount touchscreen computers.

All-in-One Computers

Other applications that are not panel mounted into an enclosure may be mounted to an arm or stand or hang on a wall. Teguar refers to these computers as All-In-One computers. All-In-One Touchscreen computers include the industry standard VESA mounting hole pattern on the back side. Because this VESA mounting hole pattern is standard, it enables a variety of mounting options that suit the needs of almost any application. Teguar offers some standard wall mount brackets and desktop stands for our All-In-One touchscreen computers, but every industrial touchscreen computer application is different. Applications that require an articulating arm, adjustable stand, or vehicle mount can utilize the standard VESA mounting hole pattern and chose from an infinite number of third party mounting options.

Other applications that are not panel mounted into an enclosure may be mounted to an arm or stand or hang on a wall. Teguar refers to these computers as All-In-One computers. All-In-One Touchscreen computers include the industry standard VESA mounting hole pattern on the back side. Because this VESA mounting hole pattern is standard, it enables a variety of mounting options that suit the needs of almost any application. Teguar offers some standard wall mount brackets and desktop stands for our All-In-One touchscreen computers, but every industrial touchscreen computer application is different. Applications that require an articulating arm, adjustable stand, or vehicle mount can utilize the standard VESA mounting hole pattern and chose from an infinite number of third party mounting options.

Teguar’s stainless steel All-in-One touchscreen panel PCs are available with adjustable stainless steel desktop mounts and stainless steel wall mount brackets. We refer to these mounting options as yoke mounts, as they attach to the mounting holes on sides of the panel PC and enable pivot and tilt functionality. These stainless steel mounting options allow users to easily change the position of the touchscreen computer and the angle of the touchscreen for an ergonomic fit for the operators.